echnical specifications

Size: NPS 1/2"-2"

Pressure: Class 150LBS-2500LBS

Body material: A105, LF2, 304(L), 316(L), F347, F321, etc

Structure type: bolted bonnet, welded bonnet, pressure seal bonnet

Basic Standard:

Design & Manufacture Std.: BS 5352 ,ASME B16.34

Face to face std.: manufacture standard or ANSI B16.10 for Flange

End connection std.: ANSI B 16.11, ANSI B 1.20.1,ANSI B.16.25,ANSI B16.5

Test standard: ISO5208 KEBV"S Forged Steel Globe Valves are Manufactured as per API 602/BS-5352 Standard and Tested to API-598/BS-5146 Standard. Bolted Bonnet, Outside screw and yoke type, Rising Spindle construction Body and bonnet made from high quality forgings.Accurately machined gate and seat rings with mirror finished seating surfaces to assure leak tightness Wedge accurately guided throughout its travel in machined guide ways in body.

VALVE DESIGN DATA

Size: 1/2"-2"

Nominal pres sure: Class 150Lb-600Lb PN1.6-4.0MPa

Material: WCB,LCB,CF8,CF8M,CF3,CF3M,A105,LF2,F304,F316,F304L,F316L

Design & Manufacture Std.: API 602 、API 6D、GB/T1237

Face to Face Std.: ANSI B16.34 、API 602 、API 6D

Flange、Thread End Connection Std.: ASME B16.5、 ANSI B1.20.1

API 608 is intended to provide the similar additional requirements for steel and alloy steel ball valves beyond

ASME B16.34 as do the following API standards for other valve types:

API 594, Check Valves: Flanged, Lug, Wafer and Butt-welding

API Standard 599, Metal Plug Valves—Flanged, Threaded and Welding Ends

API Standard 600, Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries

API Standard 602, Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries

API Standard 603, Corrosion-resistant, Bolted Bonnet Gate Valves Flanged and Butt-welding Ends

API 609, Butterfly Valves: Double Flanged, Lug and Wafer-type

ASME B1.20.1, Pipe Threads, General Purpose (Inch)

ASME B16.5, Pipe Flanges and Flanged Fittings NPS

ASME B16.10, Face-to-Face and End-to-End Dimensions

ASME B16.11, Forged Fittings, Socket-welding and Threaded

ASME B16.20, Metallic Gaskets for Pipe Flanges—Ring-joint, Spiral-wound and Jacketed

ASME B16.25, Butt Welding Ends

ASME B31.3 Process Piping

API 6FA Fire Testing of Valves

API Std 598 Valve Inspection and Testing

Would you like to get more products information or order it, please call me

|

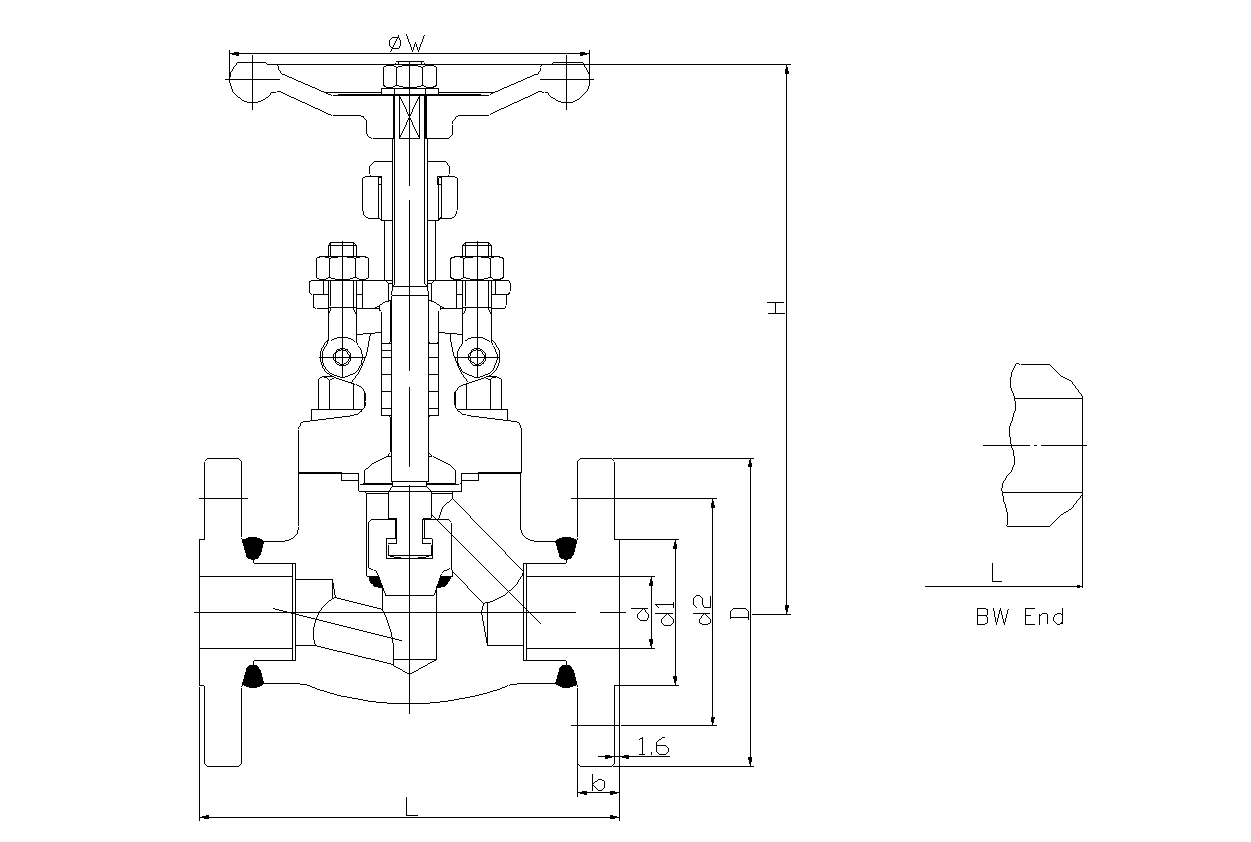

NPS |

in |

1/2 |

3/4 |

1 |

11/4 |

11/2 |

2 |

|

d |

mm |

13 |

19 |

25 |

32 |

38 |

51 |

|

L(RF) |

mm |

108 |

117 |

127 |

140 |

165 |

203 |

|

L(BW) |

mm |

108 |

117 |

127 |

140 |

165 |

203 |

|

d1 |

mm |

35 |

43 |

51 |

64 |

73 |

92 |

|

d2 |

mm |

60.5 |

70 |

79.5 |

89 |

98.5 |

120.5 |

|

D |

mm |

89 |

98 |

108 |

117 |

127 |

152 |

|

b |

mm |

11 |

12 |

12 |

13 |

15 |

16 |

|

n-Фd |

mm |

4-16 |

4-16 |

4-16 |

4-16 |

4-16 |

4-19 |

|

H |

mm |

180 |

190 |

215 |

235 |

258 |

330 |

|

W |

mm |

100 |

100 |

100 |

135 |

135 |

200 |

|

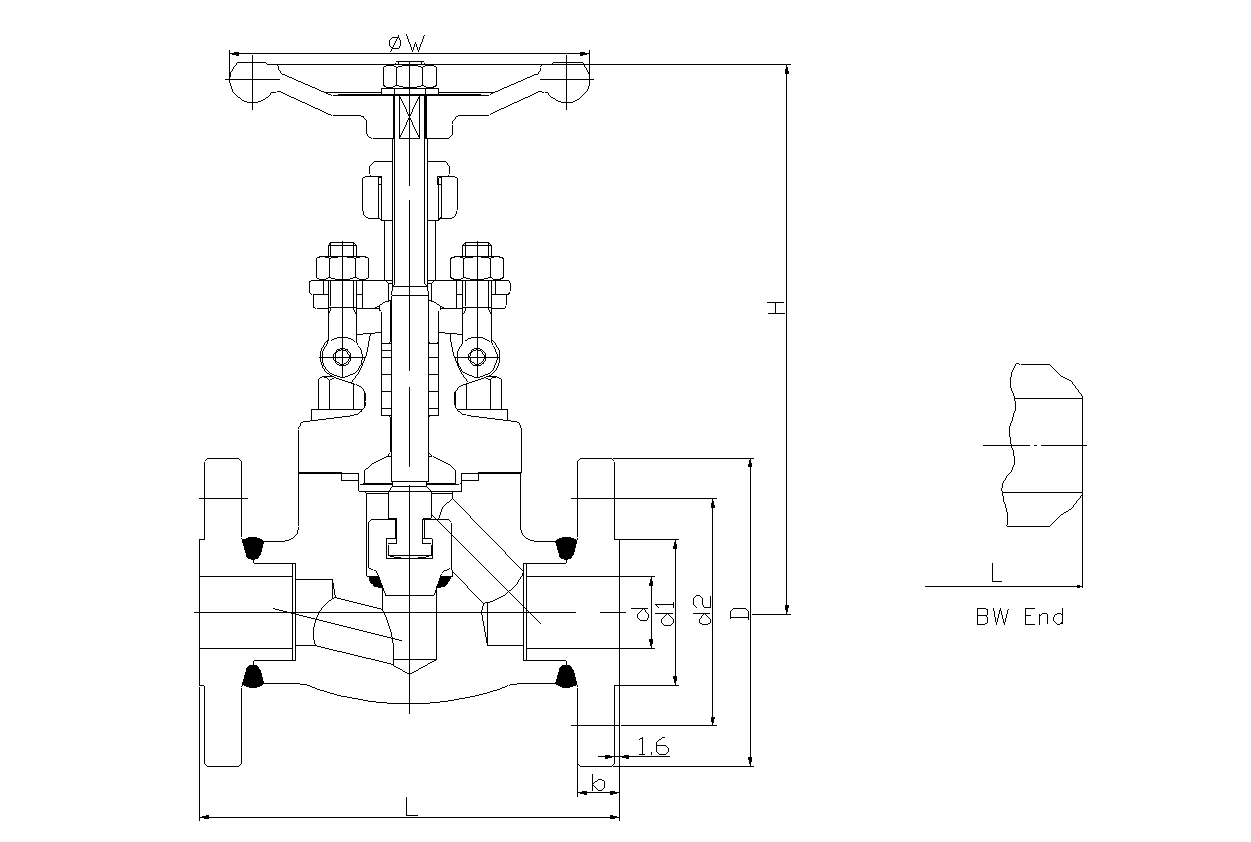

NPS |

in |

1/2 |

3/4 |

1 |

11/4 |

11/2 |

2 |

|

d |

mm |

13 |

19 |

25 |

32 |

38 |

51 |

|

L(RF) |

mm |

152 |

178 |

203 |

216 |

229 |

267 |

|

L(BW) |

mm |

152 |

178 |

203 |

216 |

229 |

267 |

|

d1 |

mm |

35 |

43 |

51 |

64 |

73 |

92 |

|

d2 |

mm |

66.5 |

82.5 |

89 |

98.5 |

114.5 |

127 |

|

D |

mm |

95 |

117 |

124 |

133 |

156 |

165 |

|

b |

mm |

15 |

16 |

18 |

19 |

21 |

23 |

|

n-Фd |

mm |

4-16 |

4-19 |

4-19 |

4-19 |

4-22 |

8-19 |

|

H |

mm |

185 |

195 |

220 |

240 |

260 |

385 |

|

W |

mm |

100 |

100 |

135 |

135 |

160 |

200 |

|

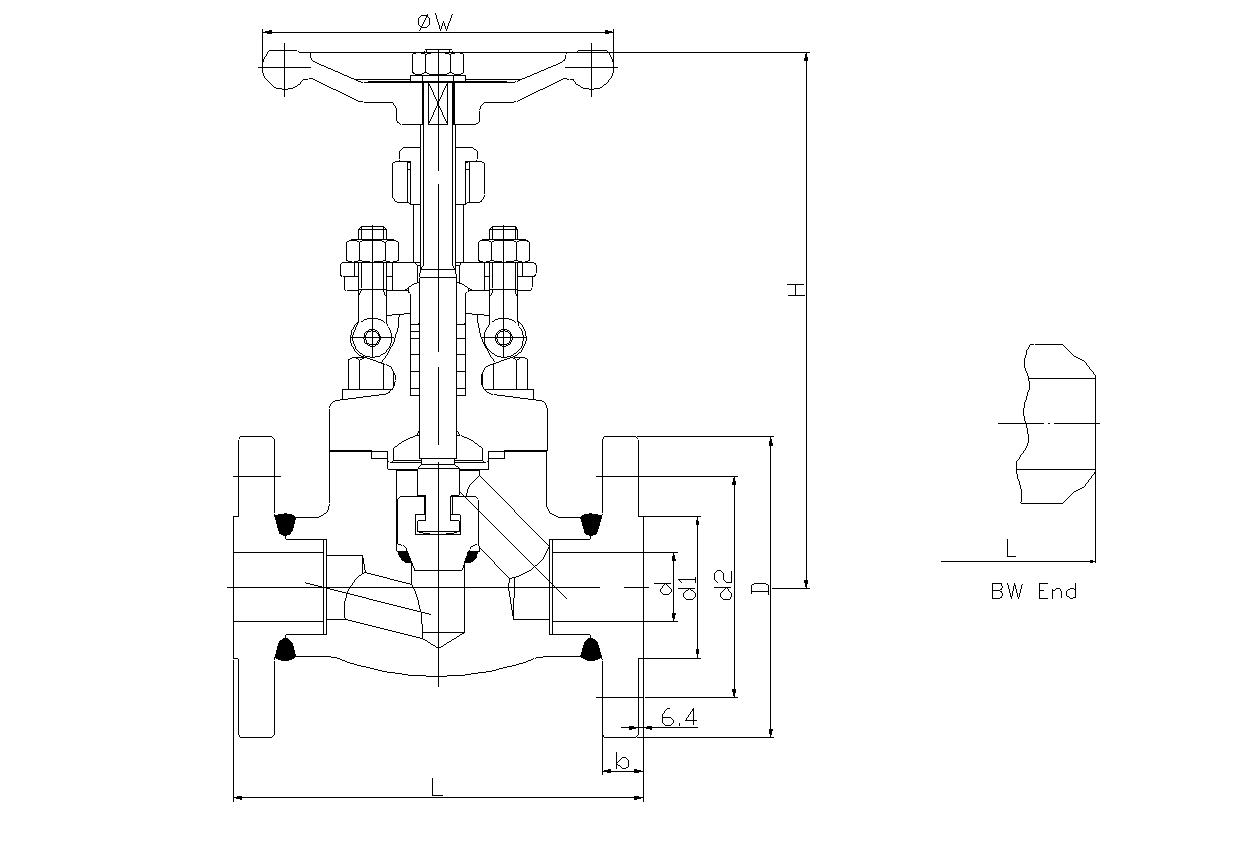

NPS |

in |

1/2 |

3/4 |

1 |

11/4 |

11/2 |

2 |

|

d |

mm |

13 |

19 |

25 |

32 |

38 |

51 |

|

L(RF) |

mm |

165 |

190 |

216 |

229 |

241 |

292 |

|

L(BW) |

mm |

165 |

190 |

216 |

229 |

241 |

292 |

|

d1 |

mm |

35 |

43 |

51 |

64 |

73 |

92 |

|

d2 |

mm |

66.5 |

82.5 |

89 |

98.5 |

114.5 |

127 |

|

D |

mm |

95 |

118 |

124 |

133 |

156 |

165 |

|

b |

mm |

15 |

16 |

18 |

21 |

23 |

26 |

|

n-Фd |

mm |

4-16 |

4-19 |

4-19 |

4-19 |

4-22 |

8-19 |

|

H |

mm |

198 |

215 |

245 |

306 |

400 |

420 |

|

W |

mm |

120 |

140 |

160 |

180 |

200 |

200 |

API Trim NO. Table

|

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

|

|

01 |

13Cr |

13Cr |

13Cr |

31 |

STELLITE |

321SS |

321SS |

|

|

02 |

304SS |

304SS |

304SS |

32 |

STELLITE |

STELLITE |

321SS |

|

|

03 |

310SS |

310SS |

310SS |

33 |

347SS |

347SS |

347SS |

|

|

04 |

HARD 13Cr |

HARD 13Cr |

13Cr |

34 |

STELLITE |

347SS |

347SS |

|

|

05 |

STELLITE |

STELLITE |

13Cr |

35 |

NICKEL ALLOY |

13Cr |

13Cr |

|

|

06 |

Cu-Ni |

13Cr |

13Cr |

36 |

A105/PTFE |

A105+ENP |

A105+ENP |

|

|

07 |

13Cr |

HARD 13Cr |

13Cr |

37 |

A105/PTFE |

WCB+ENP |

A105+ENP |

|

|

08 |

STELLITE |

13Cr |

13Cr |

38 |

13Cr/PTFE |

13Cr |

13Cr |

|

|

09 |

Cu-Ni |

Cu-Ni |

Cu-Ni |

39 |

304SS/PTFE |

304SS |

304SS |

|

|

10 |

316SS |

316SS |

316SS |

40 |

316SS/PTFE |

316SS |

316SS |

|

|

11 |

Cu-Ni |

STELLITE |

Cu-Ni |

41 |

A105/RPTFE |

A105+ENP |

A105+ENP |

|

|

12 |

STELLITE |

316SS |

316SS |

42 |

A105/RPTFE |

WCB+ENP |

A105+ENP |

|

|

13 |

ALLOY 20 |

ALLOY 20 |

ALLOY 20 |

43 |

13Cr/RPTFE |

13Cr |

13Cr |

|

|

14 |

STELLITE |

ALLOY 20 |

ALLOY 20 |

44 |

304SS/RPTFE |

304SS |

304SS |

|

|

15 |

STELLITE |

STELLITE |

304SS |

45 |

316SS/RPTFE |

316SS |

316SS |

|

|

16 |

STELLITE |

STELLITE |

316SS |

46 |

A105/NYLON |

A105+ENP |

A105+ENP |

|

|

17 |

STELLITE |

STELLITE |

347SS |

47 |

A105/NYLON |

WCB+ENP |

A105+ENP |

|

|

18 |

STELLITE |

STELLITE |

ALLOY 20 |

48 |

A105/NYLON |

304SS |

304SS |

|

|

19 |

MONEL |

MONEL |

MONEL |

49 |

A105/NYLON |

316SS |

316SS |

|

|

20 |

BRONZE |

BRONZE |

13Cr |

50 |

13Cr/NYLON |

13Cr |

13Cr |

|

|

21 |

HASTELLOY B |

HASTELLOY B |

HASTELLOY B |

51 |

304SS/NYLON |

304SS |

304SS |

|

|

22 |

|

HASTELLOY C |

HASTELLOY C |

52 |

316SS/NYLON |

316SS |

316SS |

|

|

23 |

STELLITE |

304SS |

304SS |

53 |

A105/PEEK |

A105+ENP |

A105+ENP |

|

|

24 |

304LSS |

304LSS |

304LSS |

54 |

A105/PEEK |

WCB+ENP |

A105+ENP |

|

|

25 |

STELLITE |

304LSS |

304LSS |

55 |

13Cr/PEEK |

13Cr |

13Cr |

|

|

26 |

STELLITE |

STELLITE |

304LSS |

56 |

304SS/PEEK |

304SS |

304SS |

|

|

27 |

316LSS |

316LSS |

316LSS |

57 |

316SS/PEEK |

316SS |

316SS |

|

|

28 |

STELLITE |

316LSS |

316LSS |

|

|

|

|

|

|

29 |

STELLITE |

STELLITE |

316LSS |

|

|

|

||

|

30 |

321SS |

321SS |

321SS |

|

|

|

|

|